We’ve all heard of rust, but what is “White Rust”? In this blog, we will explore all things white rust including: proper treatment, levels of severity, and preventative measures.

What is White Rust?

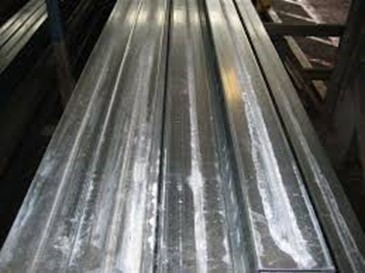

White Rust, also referred to as “wet storage stains,” is a term used to describe zinc corrosion that can form on galvanized steel surfaces. Typically formed due to poor ventilation and moisture. This results in a chemical reaction on the galvanized steel surface called zinc hydroxide. The appearance is often white, voluminous, powdery, chalky, and bulky.

Treatment Methods

Oftentimes, white rust can appear quite heavy due to it’s voluminous appearance in areas of wetness. This is can be misleading, as often times the amount of zinc corrosion is small. Although usually considered superficial, it is possible for the stain to irreversibly alter the surface of your galvanized steel. Varying degrees of stain severity can occur. Depending on the severity, there are steps you can take to help improve the appearance.

Treatment of Light White Rust

Appearance is a light film of white powdery residue. It is possible for this to be washed off in service with normal weathering. If removal of the stain is necessary, this can usually be done with a stiff bristle brush (for example: nylon). When brushing alone is insufficient, its recommended to rub the surface with a mixture of mineral oil and sawdust. This mild abrasive action may help to remove the stain.

Treatment of Moderate to Severe White Rust

Moderate to severe white rust may be removed with a wash of 10% (by volume) acetic acid solution. Followed by a thorough rinse with water to neutralize the surface. Ordinary household products like white vinegar and CLR™ have also been found to be quite effective at removal. Alternatively, a solution of 5% (by volume) of phosphoric acid in water can be brushed onto the sheets. After cleaning, the sheets must be immediately well-rinsed to neutralize the surface and then thoroughly dried.

Removal can also be assisted by using a stiff bristle brush (for example: nylon). Just note that with these treatments, you may experience some remove of the metallic luster, even on non-stained areas.

In all cases, it is crucial to let your sheets dry completely before storing or restacking. Remember to follow proper safety precautions while using any cleaning products.

Preventative Measures

The key to addressing white rust and wet storage staining is prevention. To prevent the stain from occurring, you must separate the product from any possible moisture and allow air to flow freely with proper ventilation.

Normally, your steel should be delivered to the jobsite for installation. But if site storage is necessary, we recommend that the following requirements be observed:

- Tilt bundles for drainage

- Store bundles off the ground for effective drainage and ventilation

- Block long bundles to prevent sagging

- Store away from chemically corrosive substances (e.g. salt, cement, fertilizer)

- Store away from materials that could contaminate the surface (e.g. diesel oil, paint, grease)

- Store away from site traffic

- Cover the bundles with a tarpaulin, avoid impermeable materials such as plastic

- Ensure adequate ventilation under the cover to prevent condensation

- For storage of material for an extended period of time, we recommend storing the material indoors